Table of Contents

At a Glance: A rack and pinion is the primary steering system found in most modern passenger vehicles, converting the rotational motion of your steering wheel into the side-to-side movement of your wheels. This mechanical system offers drivers precise control and reliable handling during everyday driving conditions.

When you get behind the wheel of your car, you might not think much about the engineering that allows you to smoothly navigate turns and corners. Beneath your vehicle’s hood, the rack and pinion steering system works tirelessly as the crucial connection between your hands on the steering wheel and your vehicle’s wheels on the road. Thanks to its efficient operation and dependable performance, this fundamental component has become the industry standard for modern automotive design, particularly modern cars and small trucks.

Whether you’re a car enthusiast or just trying to better understand your vehicle’s mechanical systems, gaining a better grasp of rack and pinion steering is essential. In this comprehensive guide, we’ll explore the inner workings of rack and pinion steering, examine its role in everyday driving, and explain why it’s become the preferred choice for modern passenger vehicles. From basic mechanical principles to maintenance considerations, we’ll cover everything you need to know about this vital automotive component.

Understanding Rack and Pinion Basics

A rack and pinion assembly represents the pinnacle of precision steering design, utilizing a brilliantly simple yet effective mechanical arrangement.

Core Components of a Rack and Pinion System

At its core, the system consists of three main components: the steering rack, a precision-machined pinion gear, and a pair of tie rods.

Steering Rack

This forms the foundation of the system – a hardened steel bar with precision-cut teeth along one side. This bar is housed within a robust casing that ensures smooth operation and protection from debris. The rack’s steering mechanism includes:

Steering Wheel: Turning the wheel rotates the pinion gear, allowing the driver to control the vehicle’s direction.

Steering Column This connects the pinion gear to the vehicle’s steering wheel.

Steering Shaft: Housed in the steering column, this rotates when the wheel is turned and transmits the rotation to the steering gear.

Pinion Gear

The pinion is a small circular gear that is mounted perpendicular to the rack. The pinion gear has helical or straight gear teeth that mesh perfectly with the rack’s linear gear pattern.

Tie Rods

High-quality tie rods connect the rack’s ends to the steering knuckles, translating the rack’s movement to wheel direction.

Operating Mechanics

When the steering wheel turns, it rotates the pinion gear, which engages the rack’s teeth in a precise gear-to-gear interaction. This design converts the steering wheel’s rotational motion into linear motion in the rack. The mechanical advantage provided by the gear ratio allows drivers to turn wheels that bear thousands of pounds of vehicle weight with less effort.

Types of Rack and Pinion Systems

Rack and pinion steering systems come in different configurations to suit various driving needs and vehicle designs.

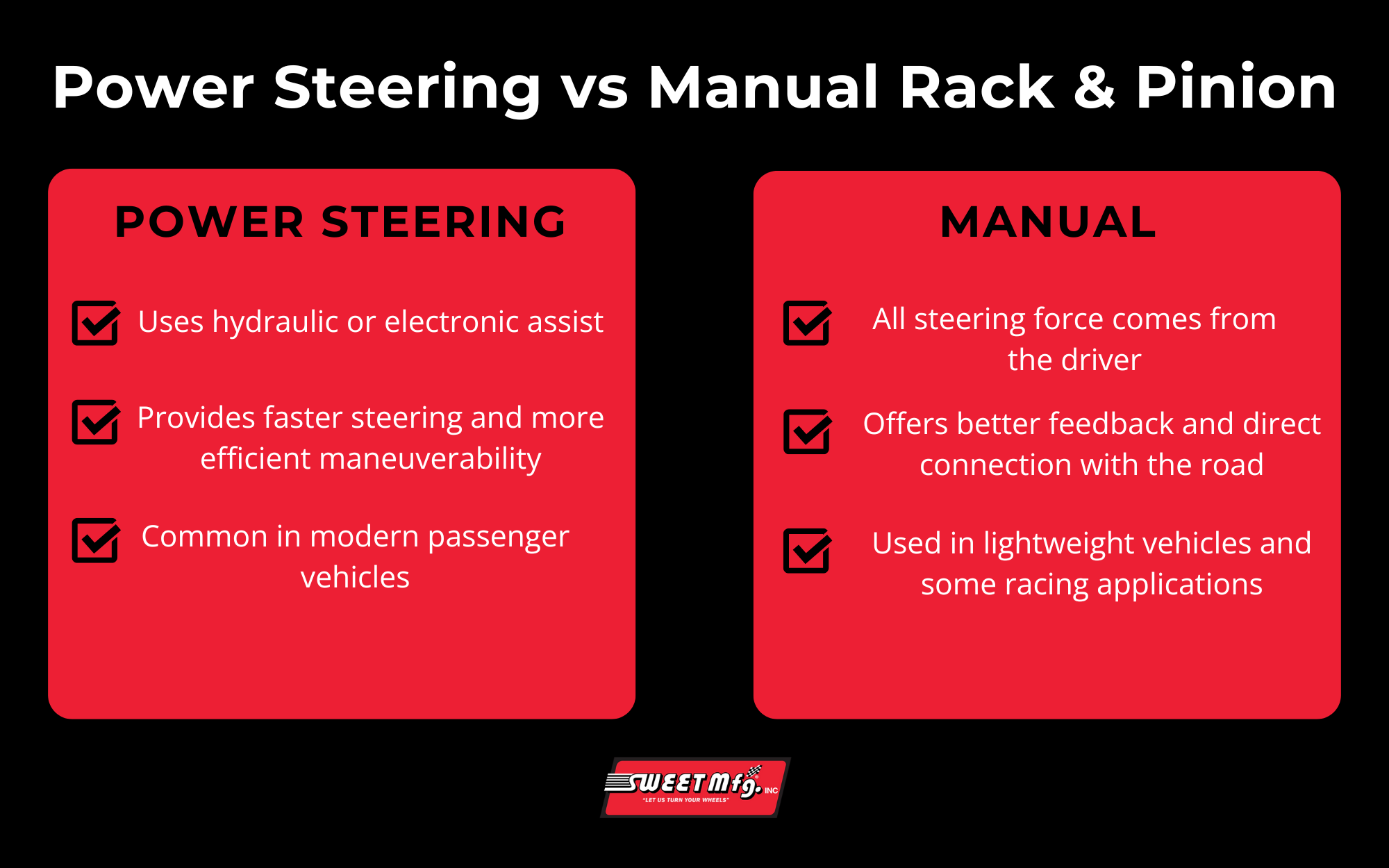

Power Steering Rack and Pinion

Power steering rack and pinion systems use hydraulic or electric assist to make steering easier, especially at low speeds or during tight turns. Hydraulic systems rely on pressurized hydraulic fluid to reduce steering effort, while modern vehicles often use electric power steering for improved efficiency and reduced maintenance. This power steering system is common in most modern passenger vehicles.

Manual Rack and Pinion

Manual systems operate without power assistance, meaning all steering force comes from the driver. While less common in modern cars, they are still used in lightweight vehicles, some sports cars, and racing applications where precise road feel, light weight, and simplicity are prioritized over ease of steering.

Maintenance and Optimization

Maintaining your vehicle’s rack and pinion system is essential for safe and reliable steering performance. Regular inspection and maintenance help ensure smooth operation and prevent costly repairs down the road.

Maintenance Guidelines

Regular maintenance of your rack and pinion system should follow manufacturer specifications. Most vehicles require periodic power steering fluid checks and replacement according to the maintenance schedule. Proper wheel alignment is also crucial, with typical toe settings ranging from 0 to 1/8 inch for traditional street vehicles depending on the model. Many racing vehicles will have staggered alignment and considerably more toe and camber.

Preventive maintenance includes checking power steering fluid levels monthly and inspecting the system’s components during routine service visits. Pay special attention to the condition of steering boots, which protect the rack from dirt and debris.

Performance Monitoring

Vehicle owners should pay attention to how their steering system feels during normal operation. Steering should be smooth and consistent, without excessive play or resistance. Any changes in steering feel, such as increased effort required to turn the wheel or unusual resistance, warrant immediate inspection by a qualified mechanic.

Detecting Common Issues

Standard rack and pinion systems can develop several identifiable problems that require attention. Watch for these warning signs:

- More than 1/2 inch of play in the steering wheel

- Stiff or inconsistent steering resistance

- Power steering pump fluid leaks

- Clunking or grinding noises when turning

Regular inspections can identify potential problems before they lead to system failure. If you notice any steering issues, have your vehicle checked by a certified mechanic who can properly diagnose and repair the rack and pinion system using manufacturer-approved procedures and replacement parts.

Racing-Specific Applications

Racing rack and pinion systems are built with specialized materials and tighter tolerances to handle intense loads with unmatched precision and feedback. These units are engineered to deliver precise control and lightning-fast response while withstanding extreme forces and temperatures inherent to competitive racing.

Rack and Pinion Maintenance for Racing

Proper maintenance of racing rack and pinion systems follows a rigorous schedule.

- Pre-Race Inspections: By focusing on checking fluid levels and examining seals for leakage, riders can more thoroughly prepare for a race.

- Between Races: During these periods, teams conduct thorough inspections of tie rod ends, steering arms, and rack housing for signs of wear or stress, as well as any developing looseness in the rack and pinion input.

- Season-Long Maintenance: This includes complete disassembly, inspection of internal components, and replacement of worn parts to ensure peak performance throughout the racing calendar. The manufacturer or a steering rebuild expert should perform this maintenance.

Racing Advantages

The direct mechanical connection provides an instantaneous response and crucial road feel that drivers rely on at high speeds. The system’s lightweight design significantly reduces unsprung weight compared to a traditional steering box, enhancing overall vehicle performance.

Additionally, the compact nature of rack and pinion units allows for optimal placement within the racing chassis, contributing to better weight distribution and improved handling characteristics. Unlike street applications, racing units typically feature reduced assistance, providing drivers with enhanced road feel and feedback crucial for maintaining control at speeds exceeding 200 mph. This efficiency translates directly to enhanced driver control and reduced steering effort, critical factors in competitive racing environments where every advantage counts.

Rack and Pinions for Different Types of Racing

Different racing disciplines demand specific rack and pinion configurations.

- Formula Racing: This employs ultra-quick ratios and minimal power assistance to maximize steering precision through technical corners.

- Stock Car Applications: These require more robust units capable of withstanding sustained high loads and elevated temperatures during long-duration events.

- Drag Racing: These racks are small, lightweight, manual, with slower ratios for more control.

Check Out Sweet Manufacturing’s Racing Rack and Pinion Products

The precision engineering of rack and pinion steering systems remains fundamental to competitive racing, delivering the razor-sharp response and feedback that drivers depend on. These systems transform subtle steering inputs into precise directional control through their elegantly simple yet robust design, with the linear rack movement providing consistent steering that racing teams can fine-tune for optimal performance.

For serious racers seeking the ultimate in steering precision and reliability, Sweet Manufacturing’s premium rack and pinion steering products represent the gold standard in performance steering technology. Engineered specifically for the demands of competitive racing, these systems feature precision-machined components, race-optimized gear ratios, and exceptional durability under high-stress conditions.

No matter what type of racing you’re competing in, we can help you find the perfect rack and pinion setup for your specific racing application. Contact our expert team to learn more about Sweet Manufacturing’s proven racing solutions.